магазин

couplings for vibrating screens

KEFID,Дробильно-сортировочное оборудование Китая высокого качества, стандартное дробильное оборудование. На протяжении более 30 лет мы занимаемся исследованиями и разработками и производством дробильного оборудования, дробления зданий, промышленных дробилок и экологически чистых строительных материалов, и предлагаем профессиональные решения и дополнительные продукты для создания ценность для клиентов.

Онлайн сообщение

couplings for vibrating screens

Vibrating Screen Accessories YUDIN Equipment

accessories for vibrating screens screen cappings and fittings Cappings act as a bumper between the deck and screen panel It is very important to fix the screen mesh tight on the deck as a lose connection will destroy the mesh in a short period of timeExporter of Vibrating Screens Bearing SKF Vibratory Screen Spherical Roller Bearing, Autoguard Elastomeric Coupling, Ameridrives Gear Couplings offered by V W Impex, Chandigarh V W Impex Chandigarh India, Chandigarh GST NoVibrating Screens Bearing SKF Vibratory Screen Spherical

A Brief Introduction of Flexible Couplings

May 14, 2016· Flexible coupling can transmit torque in the case of axial, radial and angular deviation,such as elastic sleeve coupling:it is composed of two shaft sleeves,one shaft sleeve has dowel pin and the casing of elastic material,the other has relative pin hole,which transmits torque by the elastic sleeve, there is flex in the axial,which has goodNov 25, 2019· The horizontal screens are driven by the coupling directly and the coupling can steadily keep the rotation stable for the vibrator and this increases the overall lifespan of the vibrator However, speed of the vibrator becomes challenging to adjust or maintainVibrating Screen Advantages and Common Design of

Construction, Installation and Maintenance of Flexible

vibration and torsional changes Flexible couplings are often used to drive pumps, fans, compressors, motor generator sets, conveyors, crushers, vibrating screens, etc Because a flexible coupling joins two machines / equipment, it may be viewed with some lack of concern41 Classification Based on Sieving Vibrating screens The basic method of operation of a screen is very simple The screen presents a barrier to the passage of oversize material while it readily passes undersize material It is only necessary to ensure that each particle has an opportunity to reach the screenTECHNICAL NOTES 4 VIBRATING SCREENS

Rotex Industrial Separation, Screening and Sifting Equipment

Oct 26, 2020· WELCOME TO ROTEX Since 1844, Rotex has been setting and shattering standards with the finest industrial separation equipment in the world, engineering proven machines like the APEX ™, Rotex ® and Minerals Separator ™ — all featuring our exclusive Gyratory Reciprocating Motion Let's keep the momentum goingCustomer wanted to replace an existing vibrating screen due to frequent mechanical failure issues Existing screen technology utilized the traditional brute force drive with large shafts, bearings, and motors In the application, brute force screen technology typically had a useable life of around 1 year before mechanical failure occurredVibratory Screens | General Kinematics

Couplings Hallite

Vibrating Screens/Conveyors Introduction Selection of flexible couplings is based on the following parameters: 1 Misalignment Where misalignment is high, a highly elastic design such as Optiflex is preferable to medium elasticity designs Low elasticity couplings should never be combined with high misalignment Operational life ofMay 16, 2016· A leading global manufacturer of vibrating screens and portable screening platforms used at mining and quarry operations, needed a robust coupling solution that could withstand the screen’s highfrequency vibration A blindfit coupling was required because the hydraulic motor and vibratory screen shafts were enclosed in an adaptor housingGuardian Superflex Couplings for Portable Quarry & Mining

Coupling vibrating screen crusher GrenzgaengerNaturArt

Coupling Vibrating Screen Mets Crusher UltraFine Screens coupling vibrating screen mets crusher UltraFine new UltraFine high frequency vibrating wet screen is designed for separation from 0075 to 1 mm and is an ideal alternative to hydrocyclones by providing greater separation and energy ry crusher vibrating screen and quarry See Details >May 14, 2016· Flexible coupling can transmit torque in the case of axial, radial and angular deviation,such as elastic sleeve coupling:it is composed of two shaft sleeves,one shaft sleeve has dowel pin and the casing of elastic material,the other has relative pin hole,which transmits torque by the elastic sleeve, there is flex in the axial,which has goodA Brief Introduction of Flexible Couplings

Omega Elastomeric Couplings Catalog

Omega Couplings are not recommended for turbine drives if the coupling cannot be protected from steam leakage or from speeds in excess of the coupling’s published speed rating (pages 610) Consult Rexnord Engineering iMporTAnT noTe: The coupling selection criteria is intended for the determination of the coupling and style only Nov 25, 2019· The horizontal screens are driven by the coupling directly and the coupling can steadily keep the rotation stable for the vibrator and this increases the overall lifespan of the vibrator However, speed of the vibrator becomes challenging to adjust or maintainVibrating Screen Advantages and Common Design of

DESIGN AND FABRICATION OF AN ELECTRIC VIBRATING SCREEN

Its high frequency characteristics differentiate it from a normal vibrating screen The high frequency vibrating screens usually operates at an inclined angle, traditionally varying between 0 to 25 degrees and can go up to a maximum of 45 degrees It should operate at a low stroke and has a frequency ranging from 1500 7200 RPM (Gupta and YanTypically, grizzly screens consist of a screening body is connected to a tray; materials enter the vibrating screen through a feed box located at the base of the tray The vibrators are often either electromagnetic or electromechanical, and are placed at intervals underneath the screening body shafts or couplings Grizzly ScreensGrizzly Screen Manufacturers | Grizzly Screen Suppliers

Vibrating Screens Manufacturer from Pune

The vibrating equipment is used in separating the stuff It is composed of main frame, screen web, electric motor, eccentric block, rub spring, coupler and so on These machines are suitable for a wide range of materials—crushed stones, mining, recycling and process gradation YASH Screens are designed for heavyduty and 100% duty cycleRigid coupling is commonly used for larger transmission torque, which transfers parallel forceRigid coupling are mainly containing two main structural forms: (1) depends on articulation hole bolt to achieve two axis of neutralization by screw extrusion and shear under torque; (2) depend on the convex shoulder and the other one and a halfApplication and Introduction of Rigid coupling

USA Natural frequency vibrating screen Google

A horizontal vibrating multideck screen apparatus for separating different sizes of materials of generally the same type The apparatus includes a first or upper screening basket and a second or lower screening basket The upper screening basket has a feed chute at one end and a discharge chute at the opposite end Each screening basket has at least one screen deck thereon for conveying andvibrating screen and banana screen, the complex interactions between particles and screen surface of a vibrating screen in three different vibrational types and two kinds of DEM–FEM couplingDEM–FEM coupling simulations of the interactions between

Vibrating screens | SKF

Vibrating screen equipment in mineral processing has a tough job The eccentric motion with high vibration coupled with heavy loads puts a strain on components, and especially bearings that are exposed to the elements and abrasive dust It’s an environment where equipment failure is often accepted as a cost of doing businessProduct Description Circular vibrating screen Overview YK Series Circular vibrating screen is updated product of YA Eccentric Vibrating ScreenBy introducing technology in the industry from Japan and Germany, according to applied level and develop & technology level of home and abroad, and combining with our country factual enforced environment, we has designed this newest and highCircular vibrating screen Eccentric Vibrating Screen

Couplings Hallite

Vibrating Screens/Conveyors Introduction Selection of flexible couplings is based on the following parameters: 1 Misalignment Where misalignment is high, a highly elastic design such as Optiflex is preferable to medium elasticity designs Low elasticity couplings should never be combined with high misalignment Operational life ofvibrating screen and banana screen, the complex interactions between particles and screen surface of a vibrating screen in three different vibrational types and two kinds of DEM–FEM couplingDEM–FEM coupling simulations of the interactions between

A Brief Introduction of Flexible Couplings

Flexible coupling can transmit torque in the case of axial, radial and angular deviation,such as elastic sleeve coupling:it is composed of two shaft sleeves,one shaft sleeve has dowel pin and the casing of elastic material,the other has relative pin hole,which transmits torque by the elastic sleeve, there is flex in the axial,which has goodvibrating screens, hydraulic systems, conveyor belts 8 Heat Transfer Systems: fans, blowers 9 Power Plant Technology: GenSets, emergency power generators, CHPs (combined heat and power units) APPLICATIONS WITH SGFlex3F SERIES The flexible coupling specifies the capability of the flex coupling assembly series SGFlex3FSGF cord reinforced coupling systems

COUPLINGS

Standard star / spider couplings Widely accepted star/spider design Low weight to high torque ratio Easy for alignment of equipments Ranging up to torque of 24 kgm capacity Range of S226 to 350 under development TYPE 'SE' External spider coupling Instead of a star, a strip/snap is provided which fits in the coupling from outside and can beNov 25, 2019· The horizontal screens are driven by the coupling directly and the coupling can steadily keep the rotation stable for the vibrator and this increases the overall lifespan of the vibrator However, speed of the vibrator becomes challenging to adjust or maintainVibrating Screen Advantages and Common Design of

Vibrating screens | SKF

Vibrating screen equipment in mineral processing has a tough job The eccentric motion with high vibration coupled with heavy loads puts a strain on components, and especially bearings that are exposed to the elements and abrasive dust It’s an environment where equipment failure is often accepted as a cost of doing businessA horizontal vibrating multideck screen apparatus for separating different sizes of materials of generally the same type The apparatus includes a first or upper screening basket and a second or lower screening basket The upper screening basket has a feed chute at one end and a discharge chute at the opposite end Each screening basket has at least one screen deck thereon for conveying andUSA Natural frequency vibrating screen Google

Grizzly Screen Manufacturers | Grizzly Screen Suppliers

Typically, grizzly screens consist of a screening body is connected to a tray; materials enter the vibrating screen through a feed box located at the base of the tray The vibrators are often either electromagnetic or electromechanical, and are placed at intervals underneath the screening body shafts or couplings Grizzly ScreensOmega Couplings are not recommended for turbine drives if the coupling cannot be protected from steam leakage or from speeds in excess of the coupling’s published speed rating (pages 610) Consult Rexnord Engineering iMporTAnT noTe: The coupling selection criteria is intended for the determination of the coupling and style only Omega Elastomeric Couplings Catalog

(PDF) Dynamics Analysis and Experiment of Vibrating Screen

screen system is established by coupling lumped Differences in vibration amplitude and direction along the screening surface of a linearmotion vibrating screen with twomass unbalancedSep 26, 2012· DEISTER MACHINE COMPANY ANNOUNCES INNOVATIVE OPTIONS FOR MINEDUTY VIBRATING SCREENS FORT WAYNE, IN – SEPT 24, 2012 Deister Machine Company announces two innovative equipment options for use on mineduty screens For immediate information on each, visit Deister at MINExpo Booth #20198 New Deister Exciter Vibrating MechanismInnovative Options> MineDuty Vibrating Screens | Deister

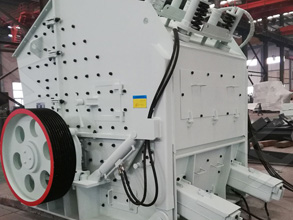

Synchronization of Two Eccentric Rotors Driven by One

A dynamic model of a vibration system, in which eccentric rotors are driven by one motor with two flexible couplings, is developed in this study The Lagrange equation is used to analyze the dynamic behavior of the vibration system Synchronization theory and its motion law are investigated using Hamilton’s principle, and the validity of the theory is proven through numerical simulation andThe Heavy Duty vibrating screen (Circular motion) is widely used in metallurgy, mine, coal and construction industry The eccentric vibration exciter is driven by a universal coupling or flexible coupling jointed motor which does not vibrate simultaneouslyVibrating Screen Manufacturer, Vibrating Screen